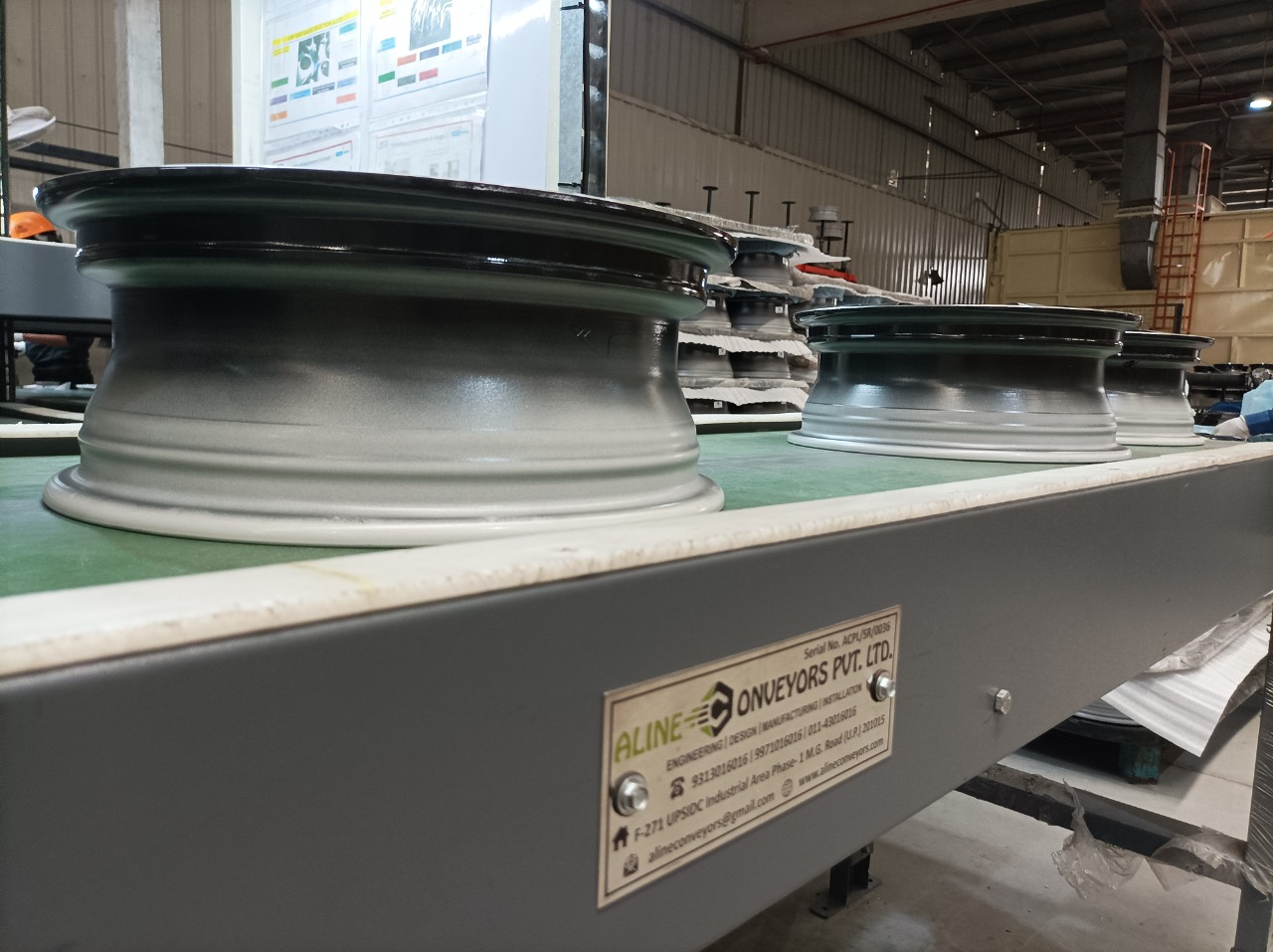

How Do Conveyor Belts Work?

A conveyor belt works by using two motorized pulleys that loop over a long stretch of thick, durable material. When motors in the pulleys operate at the same speed and spin in the same direction, the belt moves between the two.

Parts of the Conveyor Belt System

In a conveyor belt system, the aluminum profile consists of the frame, belt and any supports. Systems that use a belt are generally powered by a motor, though conveyor systems can also use gravity or manual force to function. Motorized conveyor belts are ideal for industrial use as they are more reliable and efficient — the driving unit for such systems would include the motor bracket, electrical drive and any counter bearings.

The conveyor belt system’s extremity unit typically includes any pulleys and clamping straps. Additional stands or lateral guides could be necessary for specific variations or functions, so consider your industry’s needs when choosing these optional add-ons. Parts and functions of a new conveyor belt system might include:

Conveyor Belt Uses

A conveyor system has a wide variety of uses, such as:

The advantages of using a conveyor belt system include:

Conveyor Belt Applications

The most effective method for processing, sorting, loading, and unloading passenger luggage is using a conveyor belt. Most people have seen a baggage carousel in action; it is a useful application of industrial conveyor belts where bags are loaded onto the belt in a secure location and quickly transported to the terminal where passengers can access it. For effective delivery, the belt loops back around to the baggage reclaim area after continually passing through the loading area.

Contact us right away, if you want to learn more about our wide range of conveyor belt products. Call us at +91-9971016016 or send an email to info@alineconveyors.com, we are India's largest belt conveyor manufacturers and suppliers.